Springs

Springs are elastic

members that exert forces, or torques, and absorb energy,

which

is usually stored and later released. The force produced by a spring can be

compressive

or tensile and linear or radial.

Springs are

usually,

but not necessarily, made of metal. Plastics can be used when loads are

light.

Modern structural composites are being introduced for some

applications

requiring minimum spring mass. Blocks of rubber often constitute springs, as

in

bumpers and in vibration isolation mountings of various machines such

as

electric motors and internal combustion engines. Pneumatic springs of

various

types take advantage of the elastic compressibility of gases, as compressed

air

in automotive "air shocks" and as hermetic ally sealed high-pressure

nitrogen gas in the hydro-pneumatic suspensions of French Citroen

automobiles.

For applications requiring compact springs providing very large forces

with

small deflections, hydraulic springs have proved effective. These work on

the

basis of the slight compressibility of liquids, as indicated by their

bulk

modulus of elasticity. Product cost can sometimes be reduced by designing

the

required elasticity into other parts, rather than making those parts rigid

and

adding a separate spring.

Springs can be

classified

by the direction and nature of the force exerted when they are

deflected.

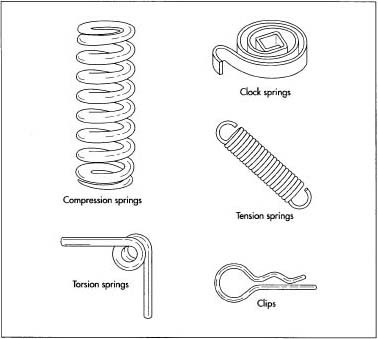

Several types of spring are listed in Table 1 according to the nature of

force

or torque exerted. The principal characteristics of various classes of

springs

are summarized in Table 2.

Table 1

Classification of springs according to

the

nature of force or torque exerted

|

Actuation

|

Type of spring

|

|

Compressive

|

Helical compression

springs

Belleville springs

Flat springs, e.g. cantilever or leaf springs

|

|

Tensile

|

Helical extension

springs

Flat springs, e.g. cantilever of leaf springs

Drawbar springs

Constant force springs

|

|

Radial

|

Garter springs

Elastomeric bands

Spring clamps

|

|

Torque

|

Torsion springs

Power springs

|

Table 2 Principle characteristics of a variety

of

types of spring

|

Type of spring

|

Principle

characteristics

|

|

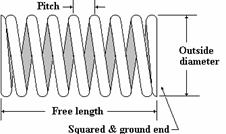

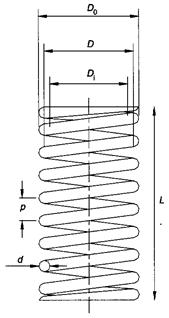

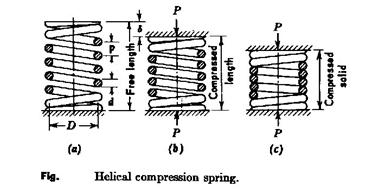

Helical compression

springs

|

These are usually

made from round wire wrapped into a straight cylindrical form with a

constant

pitch between adjacent coils

|

|

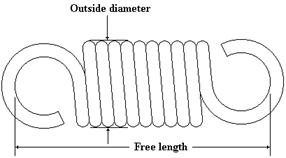

Helical extension

springs

|

These are usually

made from round wire wrapped into a straight cylindrical form but with

the

coils closely spaced in the no -load condition. As an axial load is

applied

the spring will extend but resisting the motion

|

|

Drawbar springs

|

A helical spring is

incorporate into an assembly with two loops of wire. As a load is applied

the

spring is compressed in the assembly resisting the motion

|

|

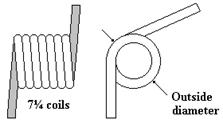

Torsion springs

|

These exert a

torque

as the spring id deflected by rotation about their axis. A common example

of

the application of a torsion spring is the clothes peg

|

|

Leaf springs

|

Leaf springs are

made from flat strips of material and loaded as cantilever beams. They

can

produce a tensile or compressive force depending on the mode of loading

applied

|

|

Belleville springs

|

These comprise

shallow conical discs with a central hole

|

|

Garter spring

|

These consist of

coiled wire formed into a continuous ring so that they can exert radial

inward force when stretched

|

|

Volute springs

|

These consist of a

spiral wound strip, that functions in compression. They are subject to

significant friction and hysteresis

|

Compression Spring

Extension Spring

Torsion Spring

Types

and configurations and spring action:

|

|

Helical

Compression

Round and Rectangular Wire

|

|

Push

- wide load and deflection range - constant rate.

Push - wide load and deflection range.

Conical springs can be made with minimum

solid height and with constant or increasing rate.

Barrel, hourglass, and variable pitch

springs used to minimize resonant surging and vibration.

|

|

|

Spring Washer

Column 1:

1)Belleville

2)Wave

3)Slotted

Column 2:

4)Finger

5)Curved

|

|

1)

Push - high loads, low deflections - choice of rates (constant,

increasing or

decreasing)

2) Push - Light Loads, low deflection-uses

limited radial space.

3) Push - Higher deflections than

bellevilles.

4) Push - for axial loading of bearings.

5) Push - uesd to absorb axial end play.

|

|

|

Volute

|

|

Push

- may have inherently high friction damping.

|

|

|

Beam

1) Cantilever, Retangular Section

2) Cantilever, Trapezoidal Section

3) Simple Beam

|

1

2

3

|

Push

or pull - wide range of loads, low dflection range.

|

|

|

Helical Torsion

Round or Rectangular Wire

|

|

Twist

- constant rate.

|

|

|

Spiral

1) Hairspring

2) Brush

|

1

2

|

Twist

Twist or Push

|

|

|

Constant Force Spring Motor

Level Torque

|

|

Twist

- exerts close-to-constant torque over many turns.

|

|

|

Helical Extension

|

|

Pull

- wide load and deflection range - constant rate.

|

|

|

Drawbar

|

|

Pull

- extension to a solid stop.

|

|

|

Constant Force

|

|

Pull

- very long deflection at constant load or low rate.

|

|

|

Retaining Rings

Round or Rectangular Wire

|

|

Pull

or push - to resist axial loads.

|

|

|

Garter Springs

1) Extension

2) Compression

|

1

2

|

1)

Pull with radial pressure.

2) Push with radial pressure.

|

Types of car suspension

springs