Types of rivets

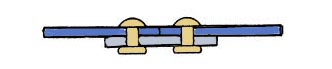

Solid rivets

Solid

rivets are one of the oldest and most reliable types of fasteners. Solid rivets

consist simply of a shaft and head which are deformed with a hammer or rivet

gun. The use of a rivet compression or crimping tool can also be used to deform

this type of rivet; this tool is mainly used on rivets close to the edge of the

fastened material, since the tool is limited by the depth of its frame.

The setting of these fasteners requires access to both sides of a structure.

Solid rivets are driven using a hydraulically, pneumatically, or electromagnetically

driven squeezing tool or even a handheld hammer.

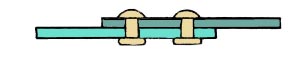

Blind rivets

Blind

rivets, commonly referred to as pop rivets, are tubular and are supplied with a

mandrel through the center. The rivet assembly is inserted into a hole drilled

through the parts to be joined and a specially designed tool is used to draw

the mandrel into the rivet.

Unlike solid rivets, blind rivets can be inserted and fully installed in a joint

from only one side of a part or structure, "blind" to the opposite

side.

|

|

|

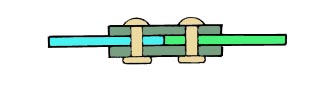

Types of riveted joints

|

Types or riveted joints |

|

|

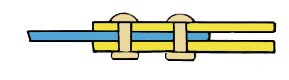

Butt Joint |

Lap Joint |

|

Single shear butt joint |

Double row, single shear lap joint |

|

|

|

|

Double shear butt joint |

Double row, double shear lap joint |

|

|

|

Lap joint: A joint formed when two surfaces overlap one another. Lap joints provide more stress resistance than butt joints.

Butt joint: A joint formed by two surfaces that meet without overlap or complex intersection. Butt joints are often combined with other joint designs.