|

Automotive Design |

Sample Exam. 1 |

(1427-1428, 2nd Semester) |

|

Student Name: |

Student No. - - |

|

ASSUME ANY MISSING DATA

1- A) Define the following:

- Safety Factor (SF):

- Second Moment of Area (I):

- Material Tensile Strength (σu):

- Allowable Stress (σall):

- Strain (ε):

B) Write down the functions

of the following parts:

|

Part name |

Functions |

|

Driving plate |

- - |

|

Diaphragm spring |

- - |

|

Friction plate leaf springs |

- - |

C) What are the requirements for the

car clutch?

-

-

-

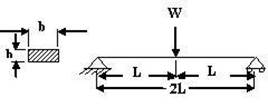

D) Write down the maximum stress equation on the member shown?

|

|

|

|

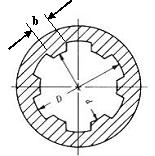

2- A) A single plate clutch is designed to transmit maximum torque (Te max) of 165 N m torque at 2400 rpm. The cultch friction plate material has the following specifications: - the coefficient of friction between the friction plate and the surfaces of the flywheel and pressure plate (μ) is 0.3 - the maximum bearing pressure (pmax) is 0.5 MPa. The friction material is connected to the leaf springs via a number of rivets: - total number of rivets is 16 - the rivet outer diameter is 3 mm - the inner diameter is 2 mm The leaf spring thickness is 0.5 mm.

Assume constant wear to the friction material, find: |

|

|

|

a) the outer radius (ro) of the friction material,

b) the inner radius (ri) of the friction material,

c) the spring force (normal force Fn).

d) the shear stress and bearing pressure on the rivets

e) Name the kind of stresses on the hub splines of the clutch friction plate

B) Draw a free hand sketch of the bolt while fastening the clutch cover to the flywheel.