|

Exam 1 |

Automotive Design |

1st semester 1429-1430 |

|

|

Student Name: |

Student Number 101- - ( ) |

||

1) ASSUME ANY MISSING DATA

1- A) Define the following:

- Material Yield Strength (σy):

- Polar Moment of Area (J):

B) Write down the function of the following parts:

|

Part name |

Functions |

|

Driven (Friction) plate |

- - |

|

Clutch cover |

- - |

|

Friction plate lateral springs |

- - |

C) What are the requirements from the car clutch friction materials?

-

-

-

D) Write down the stress formula of the following:

|

Type of loading |

Stress formula |

|

|

Force = F, strip width = B,

strip thickness = t, |

E) Draw a free hand sketch of the rivets while connecting the leaf spring and friction material of the car clutch driving plate.

|

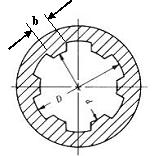

2- A) A single plate friction clutch has the following data: - outer radius (ro) = 110 mm, - inner radius (ri) = 70 mm, - the coefficient of friction (μ) = 0.3, and - number of rivets = 16. Assuming constant (uniform) wear. Calculate: (a) the clutch torque (Tc) if the spring force (Fn) = 3200 N, (b) The engine maximum torque (Te) required to operate with this clutch (c) The surface pressure (pmax) of the friction material. (d) Check if the number of rivets is enough to carry the clutch torque. The shear strength of the rivets material is 80 MPa and the pitch circle radius of the rivets is 90 mm, the area of the rivet is 4.2 mm2, the required safety factor (SF) is 3. e) the clutch cover bolt size if the number of bolts is 6 (steel EN3), SF = 3. f) Drive the shear stress on the hub splines of the clutch friction plate of length (L), using (Tc, D, d, b, n, and L)

|

|

|

|