Automotive Clutch

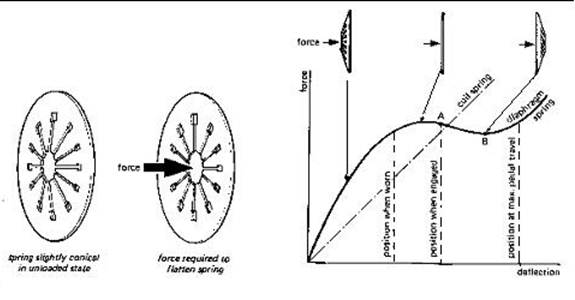

Whereas a coil spring gives a force that progressively increases with deflection, a diaphragm spring exerts a force which varies as its shape is altered. At first the force gradually increases like the coil spring but after the diaphragm spring has reached its ‘flat’ position. The force decreases and then increases once again.

When fitted to a clutch mounted on a flywheel, the spring is compressed just beyond the point where it is flat (Point A on the graph). Set in this position, the reduction in thickness of the friction facing due to wear causes the spring to ‘release’ and the force to increase.

Compared with a coil spring, the diaphragm spring offers the following advantages:

1- Compact

2- Suitable for high engine speeds. Coil springs bow outwards owing to centrifugal action and this lowers the spring force, it can also cause vibration owing to imbalance.

3- Lower pedal force, Less friction since fewer parts are needed to operate the clutch. Also the force-deflection curve suits the application.

4- Clamping force on friction facings does not decrease as facing wear.

|

|

|

Characteristic of diaphragm spring |

|

|

|

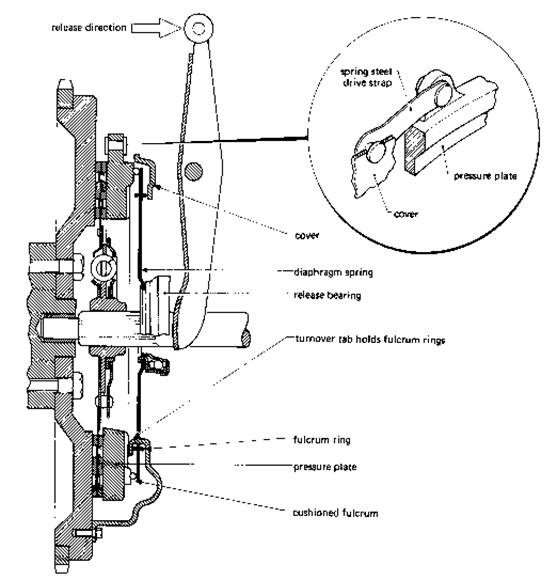

Diaphragm spring Clutch- DST type |

|

|

|

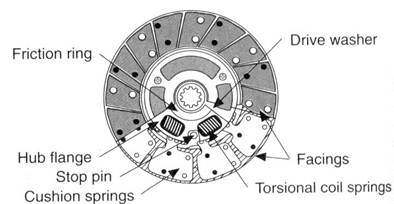

Parts of a clutch disc |

|

|

|

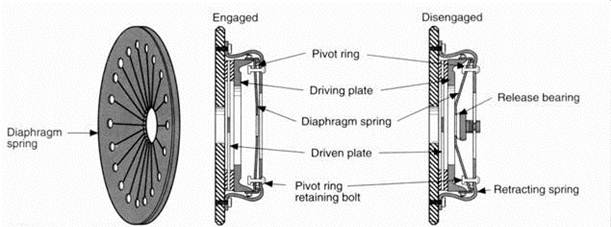

Single-plate clutch |

|

|

|

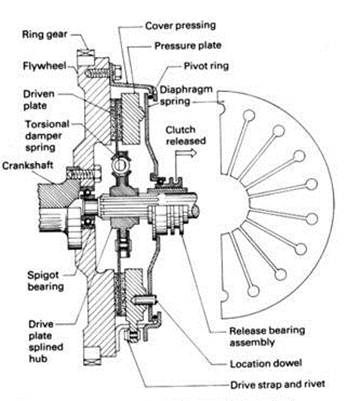

Diaphragm spring pressure plate assembly |

|

|

|

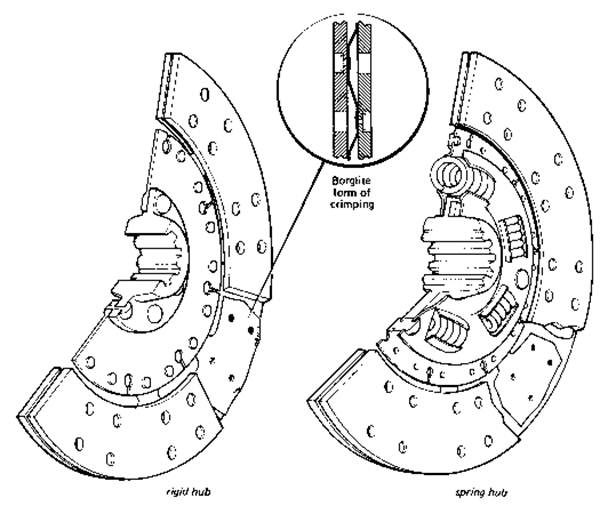

Driven plate construction. Plate cut away to show section |

|

|

|

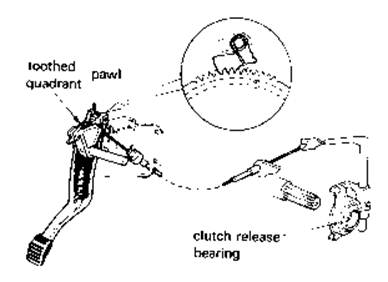

Automatic clutch adjustment |

|

|

|

Diaphragm single plate pull type clutch |

|

|

|

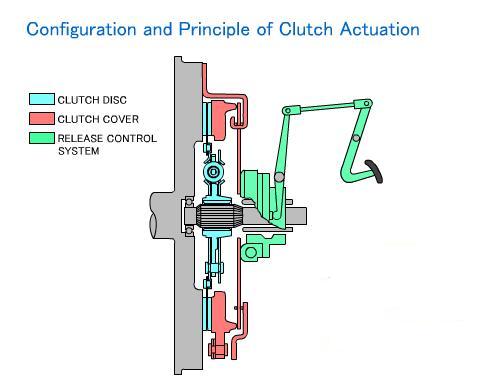

Clutch configuration |

|

|

|

Race car clutch |

|

|

|

Race car clutch |