Engine Types

Conventional car engine

A part from the benefits of traditional experience in this type of unit, the four-stroke, four- cylinder, in-line, water-cooled petrol engine has inherent advantages.

The two-stroke unit has unacceptable fuel consumption. The economy of the compression- ignition (CI) is offset by the lower power and acceleration, with increased cost, noise, weight and (to some) more objectionable fuel.

Twin-Cylinder engines have greater torque fluctuations, and six cylinder units are an unnecessary expense under 2-2.5 L capacity. The in-line layout is cheaper; fewer components are needed than for the V4 or the horizontally opposed four (H04). The usually requires a balance shaft, and H04 has complicated manifolds and cooling arrangements.

Air cooling is not suited to four-cylinder in-line units; it is noisier, requires power to drive the large cooling fan, and complicates interior heating.

Single- and multi-cylinder engines

Power/weight ratio

The engine power varies as the square of the bore (that is, with the piston area) but the mass varies as the cube of the bore (that is, with the volume of metal used). Increasing power by using a large cylinder therefore results in a low power/weight ratio, whereas increasing the number of cylinders maintains power and weight in the same proportions.

Firing interval and torque fluctuation

Since all the cylinders must fire in two revolutions of the four-stroke crankshaft, the firing interval is 720° divided by the number of cylinders. The effective power stroke occupies about 13 5°. With a single cylinder the mass of a large flywheel is required to absorb torque fluctuations and provide energy for the crankshaft. As the number of cylinders increases, torque is smoother and less flywheel mass is needed, aiding acceleration

Cooling

Large cylinders have long heat paths, such as from the piston center. Multi-cylinder units are necessary for large power to avoid lubrication and detonation problems due to overheating.

Balance and inertia loads

The single-cylinder unit can only be imperfectly balanced and vibration will occur at certain engine speeds. Four-cylinder in-line units have small secondary out-of-balance forces, while horizontally opposed; six and eight-cylinder units can have entirely satisfactory balance. The reduced reciprocating mass of the multi-cylinder engine permits higher crankshaft speeds without inertia force problems.

General comparison between 2-stroke and 4-stroke engines

|

|

Tow-stroke engine |

Four-stroke engine |

|

* Power stoke: |

* One every one rev. |

* One every two rev. |

|

* Specific fuel consumption: |

* High (at low speeds) |

* Low |

|

* Power (same capacity):

|

* High (poor power at low speeds) |

* Low

|

|

* Cost: |

* Low |

* High |

|

* Noise: |

* High |

* Low |

|

* Pollution: |

* High |

* Low |

* It might be expected that the two-stroke engine would develop twice the power of a four-stroke engine of the same size, but experience does not confirm that. The operation is less effectively carried out (loss of fresh mixture and incomplete scavenging).

General comparison between

Petrol (gasoline) Spark Ignition (SI) and Diesel Compression Ignition Engines (CI)

|

|

(SI) engines |

(CD) engines |

|

* Control type: |

* Quantity control |

* Quality control |

|

* Fuel: |

* Gasoline |

* Diesel |

|

* Ignition: |

* Spark ignition (SI) |

* Compression ignition (CI) |

|

* Compression ratio: |

* 6-9: 1 |

* 11-21 : 1 |

|

* Thermal efficiency: |

* 12% to 25% |

* 25% to 36% |

|

* Volumetric efficiency: |

* Low |

* High |

|

* Specific Fuel consumption (kW/h): |

* High |

* Lower 35% to 45% (full load) * Lower 50% (1/3 load) |

|

* Weight (same capacity): |

* Lighter |

* Heavier |

|

* Power to weight ratio: |

* High |

* Low |

|

* Max. Torque and Power: |

* High |

* Low |

|

* Fire risk: |

*Yes |

* No |

|

* Noise: |

* Low |

* High |

|

* Maintenance: |

* More |

* Less |

|

* Initial Cost (price): |

* Low |

* High |

|

* Fuel price per liter: |

* High |

* Low |

|

* Use: |

* Passenger cars |

* Trucks, busses, tanks |

|

* Maximum engine pressure: |

* 30:40 bar |

* 60:80 bar |

|

* Brake mean effective pressure (bmep): |

* 7:10 atm |

* 5:6 atm |

|

* Maximum engine speed: |

* 3500: 7000rpm |

* 2000 : 3500 rpm |

|

* Exhaust temperature: |

* 700 :1000° C |

* 500 : 600° C |

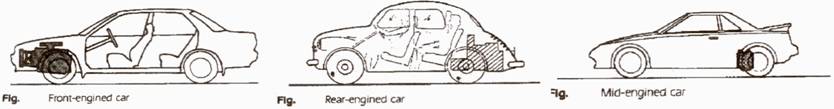

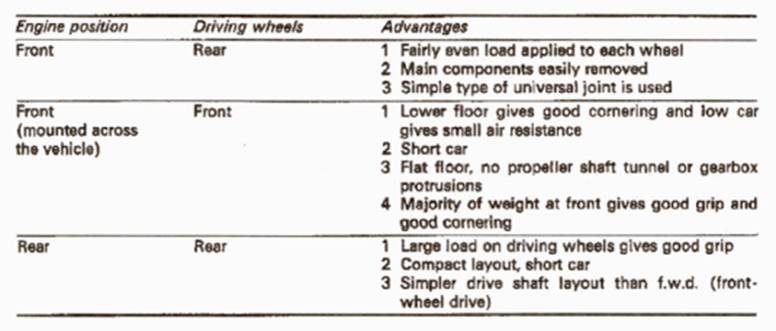

Engine Position

Front engine

The large mass of an engine at the front of the car gives the driver protection in the event of a head on collision.

Engine cooling is simpler to arrange

In addition the cornering ability of a vehicle in normally better if the weight is concentrated at the front.

Rear engine

It increases the load on the rear driving wheels, giving them better grip of the road. Most rear-engine layouts have been confined to comparatively small cars, because the heavy engine at the rear has an adverse effect on the handling of the car by making it tail-heavy. Also it takes up good deal of space that would be used on a front-engine car for carrying luggage. Most of the space vacated by the engine at the front end can be used for luggage, but this space is usually less than that available at the rear.

Central and mid-engine

These engine situations generally apply to sports cars because the engine sitting gives a load distribution that achieves both good handling and maximum traction from the driving wheel.

These advantages, whilst of great importance for special cars, are outweighed in the case of everyday cars by the fact that the engine takes up space that would normally be occupied by passengers. The mid-engined layout shown combines the engine and transmission components in one unit. The term mid-engine is used because the engine is mounted in front of rear axle line.

|

|

Drive arrangements

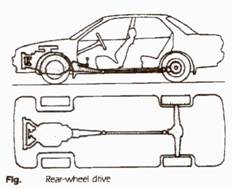

Front engine and rear-wheel drive

|

Advantages * Better axle load distribution * Better road grip * Comfort riding * Better cooling * Less noise (long exhaust pipe) * Use a long engine Disadvantages * Heavy (more weight) * The passenger compartment has the propeller shaft tunnel.

|

|

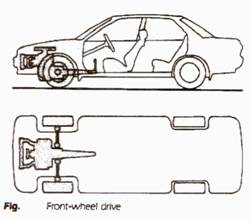

Front engine and front-wheel drive

|

Advantages * More space in passenger compartment. * Easy to place the fuel tank (bigger) * More safe in the event of head on collision. (engine mass) * Shorter car length and better passenger compartment * Better cooling * No problem in steering the car in a slippery road. Disadvantages: * The need to a power steering * More tire wear in the front axle * Less brake efficiency, 75% front and 25% rear. * Less climbing ability * Less accessibility for engine parts (maintenance) |

|

Rear engine and rear wheel drive

|

Advantages * Good brake distribution on the axles * Better climbing ability and acceleration * Less steering effort Disadvantages * More rear wheel tire wear. * Bad cooling * Less space for luggage * Sensitive to the wind. * Less safety (front fuel tank) |

|

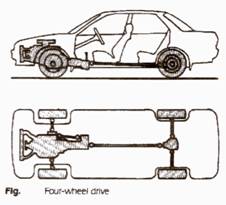

Four-wheel drive

|

Advantages * Better traction * Less risk of wheel spin * Minimizes the possibility of wheel lock-up when braking the car. * More gradient ability Disadvantages * Heavier * Increase the fuel consumption * Tire wear if driven on a paved road. |

|

|

|

The engine characteristic curve

Using the readings of the brake dynamometer we can draw the graph of the brake power and Torque against the engine revolution per minuet, where:

Pb =Te ω = Te (2π) Ne / (60 x 1000) = Te Ne / 9550 kW

Te = 9550 Pb / Ne

Where:

Pb = engine brake power (KW)

Te = engine torque (N m)

ω = engine angular velocity (1/s)

Ne = engine rev/min (rpm)

We can use the following empirical formula to draw the engine power and torque versus the engine rpm graph, by only know the max horse power and the speed at which it occurs.

Pb = Pb(max) [ A (Ne /Nb(max)) + B (Ne /Nb(max))2 C (Ne /Nb(max))3]

Where:

A, B and C are the constants of the equation

for gasoline engine:

A = B = C = 1

for diesel engine

A = 0.87, B = 1.13 and C = 1 (open combustion chamber)

Worked example:

A gasoline (petrol) engine has its maximum horse power of 80 kW at 5500 rpm. Draw the engine horse power and the torque versus the engine rpm.

Pb = Pb(max) [ A (Ne /Nb(max)) + B (Ne /Nb(max))2 C (Ne /Nb(max))3]

Pb = 80 [(Ne /5500) + (Ne /5500)2 C (Ne /5500)3]

|

Ne (rpm) |

1000 |

2000 |

3000 |

4000 |

5000 |

6000 |

|

Pe (kW) |

16.7 |

|

|

|

|

|

|

Te (N m) |

154.49 |

|

|

|

|

|

At 1000 rpm

Pb 1000 = 80 [ (1000/5500) + (1000/5500)2 - (1000/5500)3]

= 80 [(0.1818) ± (0.1818)2 - (0. 1818)3] = 80 [0.1818+ 0.033- 0.006]

=16.7 kW

Te 1000 = 9550 Pb 1000 / 1000 = 9550 x 16.7/1000 = 159.49 N m

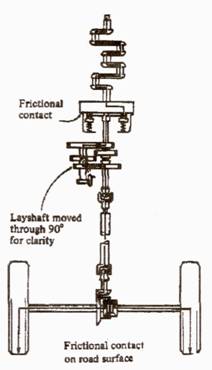

Power Transmission

Power transmission components:

|

Clutch

Gear box (transmission)

Universal joints

Propeller shaft

Final drive and differential

Live rear axle

Wheels and tires

|

|

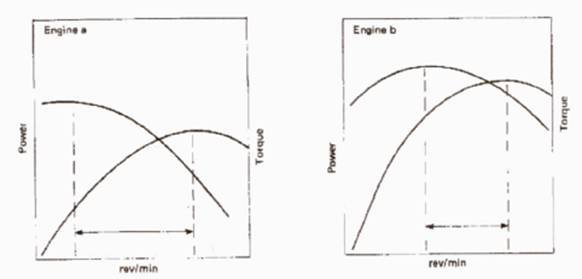

Engine characteristics and gear ratio

Study the two characteristic engine test curves for engines a, and b in the following figure. Engine a has a high torque at the lower end of the revolution rat range, which results in a flailing curve with a limited maximum power figure. However, as the working rev/mm range of the engine should be between the points of maximum tore and maximum power, this engine gives a wide range between these points, resulting in flexibility, and enables the number of gear rations to be kept to a minimum. Engine b is a more highly tuned unit having a slightly higher but flatter torque curve. The torque is also maintained at a higher figure at the top end of the revolution rate range so more power is available. Flexibility is somewhat sacrificed due to the limited working re/mm range and a four or five ration gearbox would be necessary.

|

|

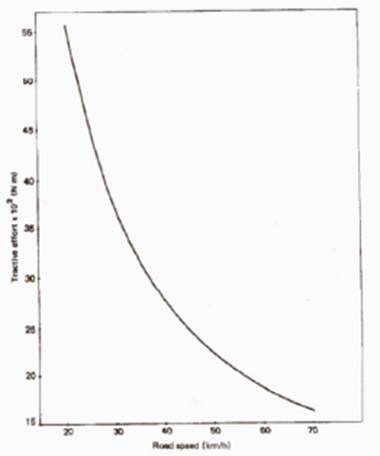

Constant power and tractive effort/road-speed curves

Since power at the road wheels is the product of tractive effort (TE) and velocity, it follows that tractive effort is proportional to the power and inversely proportional to the road speed.

vcar = ωw Rw x 3.6 =[2 π Nw/60] Rw x 3.6 (km/h)

= 0.377 Nw Rw (km/h)

(Pb)w = Tw ωw = Tw Nw / 9550 (kW)

Tw = 9550 (Pb)w / Nw (N m)

TE = Tw / Rw (N)

= 9550 (Pb)w / (Nw Rw) = [9550 (Pb)w / (0.377 Nw Rw)] x 0.377

TE = 3600 Pb / v [N]

where:

Nw = wheel revolution per minute (rpm)

Rw = wheel radius (m)

Tw = wheel torque (N m)

Pb = engine brake power (kW)

TE = tractive effort (N)

v = car speed (km/h)

A curve of constant power will produce an ideal form of tractive effort curve, and is approached by the steam engine and the series-wound electric traction motor. It could be attained with the internal combustion engine if an infinitely variable gearbox of 100% efficiency was possible.

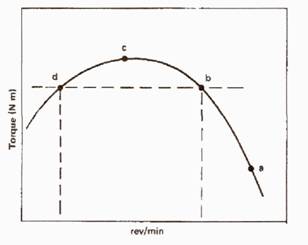

Consider the torque at road wheel, see the following figure. If the vehicle loses road speed from point a, due to increased resistance, both the road speed and engine revolutions would fall, but the rising torque may restore, a uniform road speed without the necessity to change gear. If point c or d of the curve applied, any slight increase in resistance would introduce unstable conditions due to the falling torque, and would necessitate a rapid change down to a lower gear ratio to improve the torque. The speed of stable running is a point slightly higher than that of maximum torque, such as point b, but point d would prove very unstable although it shares the same torque value as point b.

|

|

A curve of constant power is shown in the following figure. As rod speed falls the tractive effort increases in proportion to the increased resistance, thereby providing very stable conditions.

|

|

Car speed and tractive effort without reduction gears:

If we couple the engine directly to the car wheels, we will find:

v =(2 π Rw Nw) *3.6 (km/h)

where:

R = wheel radius, N = engine rpm, v = car speed in km/h

if Rw = 0.32 m,

at N=500 rpm; v = 0.377 Nw Rw = 0.377 x 500 x 0.32 = 60 km/h

at N = 6000 rpm; v = 0.377 Nw Rw = 0.377 x 6000 x 0.32 = 724 km/h

TE = Tw / Rw

where:

TE tractive effort (the wheel force) (N)

From the above we can conclude that; the petrol engine has a greater range of speeds more than required by the traffic safety, and the engine has less range of torques required to overcome the road resistances (average 2000 N). That means the engine can not run the car by itself, and it needs a reduction in speed and increase in torque.