Abstract:

The teaching process in the colleges

of technology is similar to the production process in the factories that

manufacture and produce different products and market them after that. A poor

product will not succeed in competing in the market place, which leads to its

recession, and being useless. The same concept applies to the college graduates.

If the student graduates with low qualifications or with qualifications that

does not fill the needs of the job market; this will lead to improper employment

or unemployment of the graduate.

In this paper the authors suggest a

plan to improve the technical performance standard of the college graduates, and

demonstrate through a case study the steps taken to implement that plan.

The procedure of designing a curriculum to improve the technical education is

discussed fully in the paper. The paper also includes the tables designed to

tabulate data and facilitate the construction of the curriculum.

Key words:

Educational Plan Creation, Curriculum Design, Syllabus Development, Teaching

Staff Training, Workshop Equipment Assessment, Teaching Methods Implementation.

1. Introcuction

The General Organization for Technical

Education and Vocational Training (GOTEVT) plays an important role in providing

the technical job market with well-qualified workforce. The GOTEVT

receives the high school graduates as a raw material and shape them into fine

skillful workers in their field of specialty as a finished product.

The graduate of the technical colleges

differ from the university graduate in that he is evaluated on the basis of his

practical ability and skills not his theoretical knowledge, and he is usually

evaluated according to his expertise in the workshop and his manner in carrying

out the disassembling and assembling of the parts and performing the maintenance

operations needed.

The quality of the graduate is

measured mostly upon his practical capabilities, and stating that the graduate

is weak and unable to compete in the job market

arises from that concept. To prepare the graduate to be able to compete in the

job market GOTEVT should implement a suitable plan, this plan can be divided

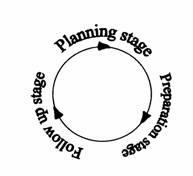

into three stages as can be seen in Fig. 1, a similar concept can be seen in

Reference 1.

A- Planning stage:

a- Determining the type of students

enrolled in the colleges (general certificate of secondary education or

industrial certificate of secondary education), taking into consideration the

suitable teaching plan for them, based on their previous education status.

b- Studying the needs of the job

market, in the present time and in the few years to come so as to determine the

job qualifications needed in the graduates and also determining the sufficient

numbers of graduates required.

c- Determining the desired level for

the graduate and his job title.

B- Preparation stage:

a- Establishing an education plan

which would get the student (general and/or industrial certificate) to the

capability level needed for the job named in the planning stage.

b- Setting a curriculum that would

fulfill that education plan.

c- Supplying the laboratories and

workshops with the equipment and special tools suitable for the tasks outlined

in the curriculum.

d- Hiring teachers qualified in the

field subject to teach the curriculum.

C- Follow up stage:

a- Follow up on the graduate’s job

situation.

b- Follow up with the companies at

which the graduates were hired to gather feed back information about the

weak and strong points of the graduate.

c- Monitor the change in the needs of

the job market to modify the planning stage accordingly.

2. Case study

This paper reflects the opinion of the

authors to establish a plan to make a contribution in the development of the

technical education in the Department of Mechanical Technology, Automotive

Section.

This study can be applied to the

other departments of the college

A-

Planning stage

This stage in the current situation

needs more careful study for the automotive job market from the time being and

through the next three years, to make reliable predictions to insure that the

college graduate, with the qualifications he gained in college, can find the

suitable job when he finishes college.

Determining the qualifications needed in the graduate

The need is for an auto mechanic and

electrical technician to deal with most of the private cars and vans in the

kingdom in general, who is capable of doing the following:

o

Knowing the use of

the general tools and has the knowledge of the workshop safety rules and

precautions.

o

Has the ability to

read the car manuals and understanding car specifications and can read charts

and technical drawings.

o

Performing the

required maintenance operations needed for the cars.

o

Checking and

inspecting the car and has the ability to use the diagnoses equipment and

analyzing the obtained results.

o

Being capable of

following a logical method and specific steps to diagnose the car problems.

o

Has the ability to

disassemble and assemble car parts, correctly and efficiently.

o

Can examine parts

using measuring equipment and can judge their condition.

o

Capable of specifying

the spare parts needed and knowing how to use the spare parts catalog.

o

Has the skill to

replace the faulty parts with the good ones and make a final check.

o

Can repair the

repairable systems parts.

o

Can handle the

workshop paper work and management.

o

Has the ability to

follow orders and work in a team.

B-

Preparation stage

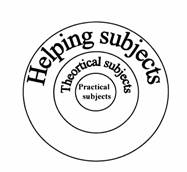

The education plan in the vocational

and technical colleges consists of the three sides of the golden triangle (the

curriculum, the teaching staff and the workshop equipment) as shown in Fig. 2.

In this stage the need for a

well-prepared curriculum is essential, there should be an arrangement between

the teachers of the practical and theoretical subjects. The subjects in the

semesters should be taught in a sequential order. Add the new (up to date)

technology subjects, and remove the ones that are not in accordance with the

desired qualifications of the graduate.

Special attention should be given to

the teaching staff, the theoretical teachers should have good knowledge in the

field, and the practical teachers should have good experience in the workshop

operations. Periodical training sessions are necessary to keep them well

informed with the new technology in the car industry.

The equipment and parts needed for

training in the workshops play an important role in the practical education

process. Some of the needed equipment are not available in the workshop,

or are insufficient for the number of students who will use them, or they might

be not up to date. It is also important to mention here that; even the equipment

currently available in the workshops are not 100% utilized: some of them are not

in a good working condition, missing parts, and in some cases their operational

manuals are missing. In some other cases the practical teachers do not

have the experience necessary to operate them.

Designing the curriculum

To cover all the work needed to

maintain the car, the study of the car can be divided into subjects according to

its major systems (engine, gearbox, brakes, ….etc.). Where each subject covers

one of the car systems theoretically and practically.

The theoretical study includes the

theory of operation, systems construction, systems types, systems main parts and

the functions of each part and the relationship between the different parts.

Also the theoretical part includes the system performance, functions and

operation calculations. Example of that can be seen in Reference 2.

The practical studies on the other hand include the identification of system

parts and their operation problems, the cause of common problems, the use of the

diagnoses equipment to trace the system and parts malfunction. Also, include the

use and care of the tools to disassemble and assemble parts, the use of workshop

special measuring and inspection tools to adjust, fix and replace parts. Example

of that can be seen in Reference 3.

To reach the goal of designing a sound

curriculum a complete work plan should be established and the following steps

could be implemented.

·

Determining the

necessary (main) subjects (courses) to achieve the graduate qualifications. This

can be done according to the car main systems (engine, gearbox, brakes …. etc.).

·

Determine the level

of information needed for each subject. This can be determined according to the

job title and qualifications.

·

Determine the number

of hours needed for each subject according to the level and difficulty of the

subject.

·

Select the helping

(aiding) subjects which substantiate the main subject and help in explaining the

basic rules and theories for car systems operation, such as physics, math,

mechanics, material properties, engineering drawing.....etc.

·

Select the

introductory subjects such as basic workshop operations, computer applications

...etc. which help in developing the student’s practical skills.

·

Determine the

language of teaching according to the market demands and the references and

manuals available, and the teachers’ personal ability to teach in the selected

language.

* Some other subjects can be added to

enhance the student’s main knowledge and moral and ethic behavior such as

religious study, job ethics.... etc.

Developing

the syllabus for each subject (course)

As mentioned above, the curriculum of the automotive technology section consists

of a number of subjects (courses) each subject will cover one system of the car

(engine, gearbox, brakes, ….etc). To develop a syllabus for any of these main

subjects certain steps should be followed. The method suggested here is to start

with the workshop operations (job tasks) needed to be covered to attain the main

graduate’s qualification needs, and then determine the theoretical subject

matter that will be needed to cover the workshop operations. Then choosing the

helping subjects that will be selected to explain the basics of the theoretical

subjects, as can be seen in Fig. 3. This can be done in the following steps:

1.

Define the

semester schedule:

The semester on average consists of 15

weeks; the work through the15 weeks can be divided as follows:

1 week,

introduction to the safety rules when working in that particular workshop, also

to know the common and special tools used in that workshop.

12 weeks, to carry out the job tasks of maintenance and

repair of the car system.

1 week, to revise the work done

during the semester.

1 week, to carry out the final

exam.

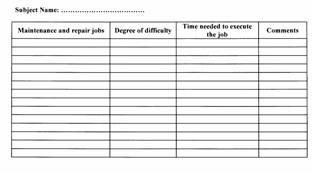

2.

Determine the job

tasks

With the help of the experts in the

automotive field, the textbooks and the shop manuals, we can decide what jobs

are needed to be covered during the practical teaching of the subjects. The

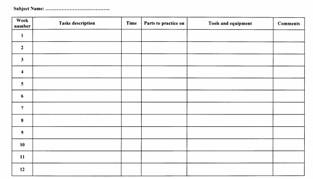

obtained data can be tabulated in Table 1. Using Table 1, we enter the job and

the average time needed to carry it out (taking into account different car makes

and models). The familiar jobs can be grouped together, or big jobs can be

divided into small jobs to end with 12 equal tasks having nearly the same time

duration. Also the jobs can be executed through the semester in a certain order

so that we start with the tasks of less difficulty.

The 12 tasks can then be entered into

Table 2. Table 2 contains the tasks, their time duration, the parts needed for

training for each task, the hand and special tools and the equipment needed to

carry out the tasks.

3.

Determine the time

duration of the practical class

To estimate the time needed per week

to carry out the tasks we use Table 2. In the third column of Table 2 the

average time in minutes for each task is located, then we add to this time

fifteen minutes at the beginning of the class to prepare for executing the job

and another fifteen minutes at the end of the class to collect the tools and

clean the working area. Then divide the time obtained by 50 minutes (the class

period) to obtain the number of practical classes per week needed to carry out

the scheduled tasks.

4.

Determine the

parts needed to practice the tasks

From Table 2 the parts needed for

practice are tabulated in the forth column, multiplying the number of different

parts by the number of students in the working area at one time will give us the

number of the parts needed for practice. This information can be used when the

college orders parts for training for each workshop.

5.

Determine the

tools and equipment in each workshop needed to execute the tasks

In Table 2 the equipment needed to

execute the tasks are tabulated in the fifth column, multiplying the number of

equipment needed by the number of students in the working area at one time will

give us the number of the tools and equipment needed. This will facilitate the

preparation of the equipment order list for the college.

6.

Determine the

theoretical subject matter needed to cover the practical subjects

After knowing the practical subject

matters needed we then can determine the theoretical subjects needed to help the

student understand the tasks more fully. We can use Table 3 to list all the

relevant theoretical subjects that cover the practical subjects and enter them

in the fourth column, and include the time needed in minutes to fully teach

those subjects in the fifth column. In the sixth column we decide the degree of

importance of teaching that subject to the college student based upon the level

of qualification needed for the graduate. Multiplying the weight factor of each

choice by the time needed in the fifth column will set the teaching time for

that subject. Adding the total time in the seventh column will give the total

teaching time needed to cover the theoretical aspects. Dividing the total time

in the seventh column by 12 weeks will give the number of minutes per week to

teach the theoretical subjects. Dividing this time by 50 minutes will give the

number of classes needed to teach that subject per week. By using this method we

can decide the number of theoretical classes and number of hours allocated to

teach each subject.

7.

Determine the

order of teaching the practical and theoretical subject matter

In the workshop we can start from easy

tasks to more difficult ones, like the system and parts identification then the

inspection of the system followed by the periodical maintenance to repair jobs.

The theoretical subject matter

relevant to each task should be taught ahead of executing this task in the

workshop.

8.

Determine the

helping subjects that will help the student’s further understanding and improve

his performance

To enhance the student’s ability,

other helping subjects should be taught at the same time. By knowing the

theoretical part of the subject matter we can choose the subjects that will

explain the principals and basics that the theoretical part is based upon, such

as physics, math, mechanics and material properties. Also a course in

preparatory workshop and computer applications will improve the student

performance.

* After we determine the practical

subjects, the theoretical subjects and the helping ones, and knowing the number

of hours needed, one final step is needed to finish writing the curriculum and

that is the sequence of teaching the subjects. This can be done according to the

order in which one subject is dependent on the other, and the number of credit

hours available in each semester.

The following figures are obtained

from Reference 4 which has a teaching plan (Automotive Mechanics Technology)

similar to the one taught in the Colleges of Technology, Department of

Mechanical Technology, Automotive Section.

Total number of credit hours is 76

hours, divided as 75% technical subjects and 25% helping subjects. These credit

hours are equivalent to about 129 contact hours. The contact hours are divided

into 68% practical subjects, 17% theoretical subjects and 15% helping subjects,

this is equivalent to 4 : 1: 0.88 respectively .

The teaching

and training staff

Teachers of the major (main) subjects:

Their major task is to explain the

basic theories and functions of car systems. The teachers hired should be

qualified to do this job, either have background education (a degree) in the

automotive field or have good experience in that field.

Teachers of the practical subjects in

the workshop:

They should be qualified to explain

the tasks before

hand, demonstrate the method applied, to show the safety precautions used,

and have the experience to perform the maintenance and repair tasks and the

skills to use the tools and equipment Those teachers should go through

training programs that keep them abreast with the new technology in their field

of specialty, their ability and performance should be continually evaluated,

refer to Reference 5.

The

facilities, equipment and parts for training

Each college should have adequate

equipment, cars and car parts for the students to practice on to give the

student hands on experience. This can consist of

Ø

Hand tools, and

special tools for doing the jobs of disassembling and assembling of the car

parts.

Ø

Measuring tools, to

measure the dimensions of various parts to determine their condition.

Ø

Diagnosing equipment

to test and analyze the data or results.

Ø

Cars or parts of cars

that the students can practice on.

Ø

Transparencies and

posters of the different systems of the car.

Ø

Textbooks and

references and manuals for different car makes and models.

Ø

Video tapes, teaching

aids and computer software.

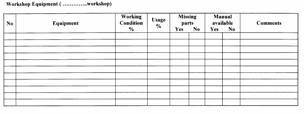

Since the workshop equipment plays an

important role in the education plan, the authors suggest the following:

* The workshop equipment currently

available could be listed and their conditions evaluated as in Table 4, and any

other piece of equipment needed to carry out the tasks should be purchased.

* Carry out the necessary equipment

repairs to make the defective ones functional.

* Fill any shortage in equipment spare

parts, and manuals.

* Lay a plan to update the workshop

equipment.

* Lay a plan to train the practical

teachers to use the equipment efficiently.

* Lay a maintenance plan for the

workshop equipment, to keep them in good working condition.

Teaching

methods

Teaching language

Teaching in English or in Arabic each

has its positive and negative points.

Teaching in English hinders the

student’s full understanding of the subject matter taught in the class, and it

will be difficult to judge the student’s level of understanding because the

tests are written in English. Also not all the teachers can teach and pass the

information on to the students in English.

On the other hand, teaching in Arabic

has its drawbacks from the point of view that there are no reliable technical

references written in Arabic. The manuals and apparatus keys and buttons and

display screens are written in English. Most work environments use the English

language.

Here we suggest that:

* Teaching could be in Arabic in

addition to explaining the technical terms in English.

* The GOTEVT should start writing its

own textbooks, in Arabic, to cover the curriculum used.

* Add English language courses to the

helping subjects to raise the student’s level of understanding of the technical

terms, and help him to use the technical manuals.

Workshop tasks

Since the tasks for the student are

determined beforehand, then it is suggested here to give the student a handout

for each task similar to the one shown in Appendix A. The student can fill

it out and hand it in at the end of the workshop class. This will help the

student to know how to use the work order sheet, also it can be a good document

for evaluating the student’s performance in the workshop.

Tests

and Exams

The tests could be based upon certain

standards (as Automotive Service Excellence (ASE) certification-type questions,

for example), see References 2 and 3.

C- Follow up Stage

This stage is overlooked despite its

great importance in making the educational plan a success.

A committee of specialized people from

the teaching staff and from the automotive field can be established to monitor

the changes in the market and to update the curriculum to be abreast with the

new developments in car industries. The duty of this committee is also to choose

the textbooks that are suitable to that curriculum.

3. Conclusion

-

Good planning will result in

a qualified college of technology graduate who can compete strongly in the

job market.

-

To achieve this goal this

plan can be executed in three stages. The planning

stage, the preparation

stage and the follow up stage.

-

In the planning stage a

careful study should be carried out to determine the job market demand and

the graduate qualifications needed.

-

In the preparation stage a

curriculum should be designed to give the graduate the qualifications needed

to strongly compete in the job market.

-

Designing a curriculum for the college of technology students should start

by determining the tasks needed to be executed in the workshop for each

subject and then followed by determining the theoretical subjects needed for

the students to understand the theory behind the practical subjects. This is

accompanied by a selection of helping subjects to explain to the students

the basics and theories used in the theoretical subjects.

-

The syllabus of each subject

should be carefully prepared, to determine the subject matter and the

teaching time.

-

Table 2 can be used to

determine the order of executing the workshop tasks, the executing time, the

parts needed for practice, and equipment and special tools list.

-

Special attention should be

directed to the selection and hiring of teachers, and to the training plan

to improve their ability and performance.

-

The college equipment should

be listed and sorted according to their working condition, their manuals

availability, and their role in the practical teaching plan, and the

ability of the teachers to use them effectively.

-

The teaching method and

proper teaching facilities in the college plays an important role in

developing the technical education.

-

The follow up stage is very

important to gather feedback so as to continuously modify and improve the

curriculum to accompany the changes in the job market demands and the

development in the car industry’s technology.

4.

References

1. Dandaachi, J.M.A, Ahmed, K.A,

Mullah, S.T, “Quality Assurance in Education in Colleges of Technology an Urgent

Tool for Accomplishing Partnership with the Industry”, First Saudi Technical

Conference & Exhibition, Riyadh, 2000.

2. Webster, Jay and Owen, Clifton E.,

“Basic Automotive Service & Systems”, Classroom Manual, Today’s Technician

series, 2nd

Edition, Delmar- Thomson Learning, 2000.

3. Webster, Jay and Owen, Clifton E.,

“Basic Automotive Service & Systems”, Shop Manual, Today’s Technician series, 2nd

Edition, Delmar- Thomson Learning, 2000.

4. Automotive Mechanics Technology

course Syllabus, Southern Union State Community College, Opelika, Alabama, USA.

5. Koike, Sumiylshi, “Developments and

Training in Technical Education for Japanese Teachers”, First Saudi Technical

Conference & Exhibition, Riyadh, 2000.

Fig. 1 Stages of the education plan.

Fig. 2 The

three important elements in the education plan for the vocational and technical

education.

Figure 3: The suggested method for

designing the curriculum.

Table 1: Designed table to determine workshop tasks.

Table 2: Designed table to determine the order of executing tasks, parts

needed for practice and workshop tools and equipment.

Table 3: Designed table to determine the theoretical subjects needed and their

estimate teaching time.

Table 4: Designed table to list the workshop equipment and their working

conditions.

Appendix A

(Task-sheet example)

Student Name______________________

Date_______

Student Number_________________

Group_________

Objective:

Inspect a vehicle designated by your

instructor to determine the type of brake system used and the identification

of brake-system components. Write down your findings in the spaces provided

on the task sheet.

Make of

Vehicle_________________

Model_________ Year______

1. Type

of brake system.

Four-wheel disc_____ Front disc/rear

drum____

Vacuum booster______ Hydraulic

booster____

Combination vacuum/hydraulic

booster____

2. Hydraulic System.

Front-rear split____ Diagonally

split____

Metering Valve: Yes____

No____

Proportioning Valve: One___

Two___ None____

Brake-warning-light switch:

Yes____ No____

Combination Valve: Yes____

No____

3. Stoplight switch.

Mechanical ____ Hydraulic____

Location________________________________

4.

Hydraulic tubing.

Is tubing

coil spring protected anywhere? __________________________________

Tubing outer

diameter________

5.

Parking brake.

Hand

operated_____ Foot operated_____

Parking

brake operates on:

Drum

brakes_____ Disc brakes____

6. Antilock brake system.

Antilock brake system:

Yes____ No____